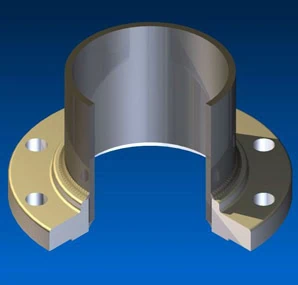

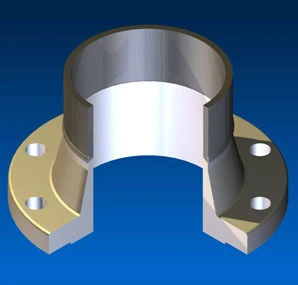

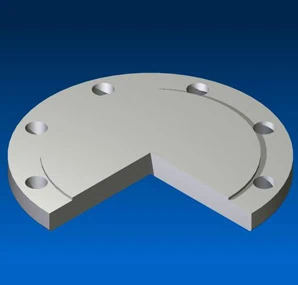

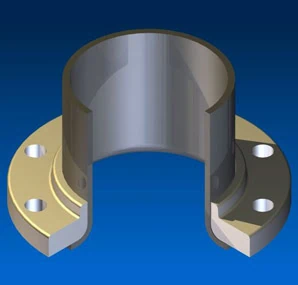

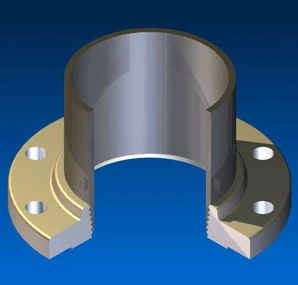

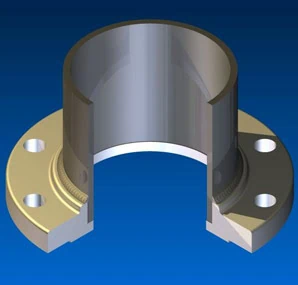

A pipe flange is a disc, collar or ring that attaches to pipe with the purpose of providing increased support for strength, blocking off a pipeline or implementing the attachment of more items. They are usually welded or screwed to the pipe end and are connected with bolts. A gasket is inserted between the two mating flanges to provide a tighter seal. These flanges are either custom with dimensions provided by the customer or they are manufactured according to published specifications. Several organizations and associations have published specifications that provide dimensional information as well as pressure specifications at different temperatures. Our company manufactures custom designs and stocks six basic types of these products. Although, these are the six most common types, we are a custom manufacturer as well and are able to create just about any type of flange necessary for your requirements. Please click on one of the following pictures for a more detailed description of the item you are interested in. Each page also has a video that provides a better understanding of the installation process.