With a wide range of industries, shops, and systems dependent upon high performance flanges, custom pipe flanges are often essential to getting a job done right. Modified and custom flanges for specialty projects can offer the same quality, inspection requirements, and performance expectations of industry standard components, but offer a particular size, material, or fit for a unique application.

How does custom flange manufacturing work?

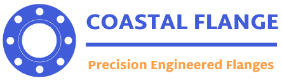

Job shops specializing in custom work often stock large quantities of raw material ready to be crafted into the shape, size, and style of flange a customer requires. This includes modifications on industry standard flanges or unique shapes such as:

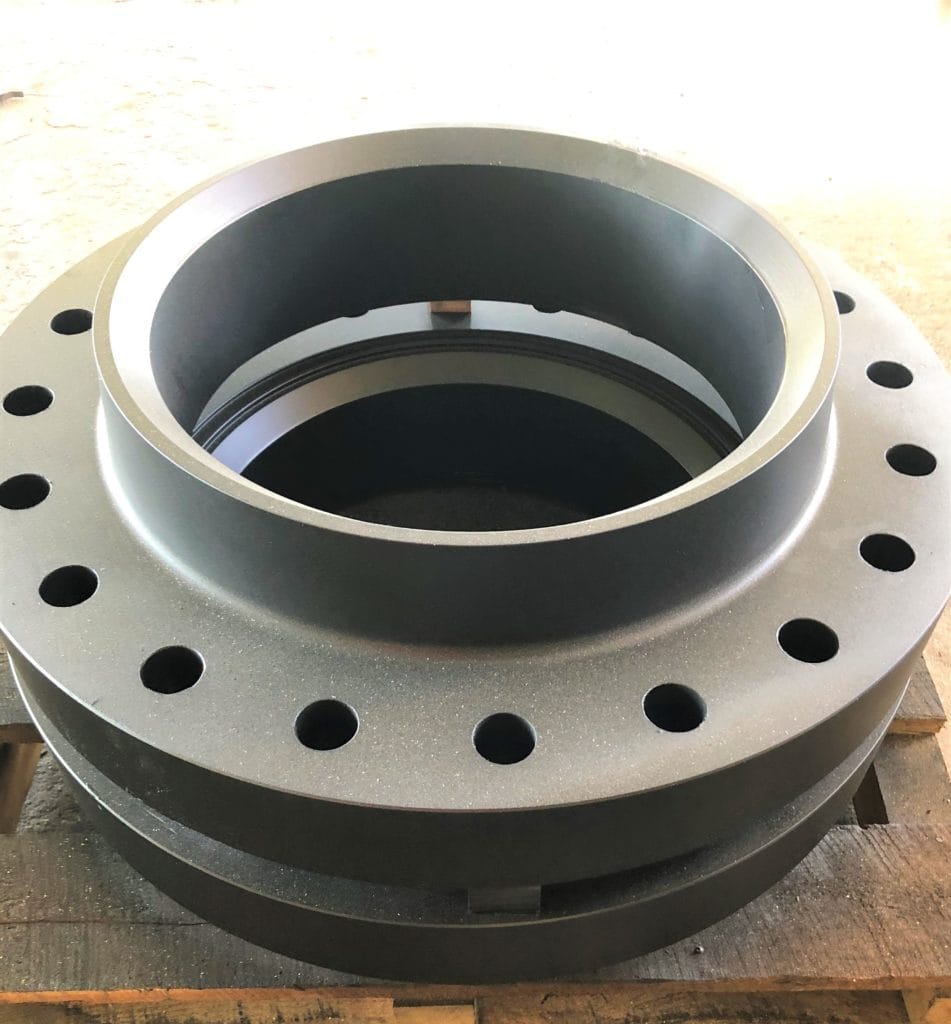

- Square Pipe Flanges

- Square OD x Circle ID Flanges

- Flanges with dual bolt patterns

- Flanges with spools between custom layers

- Reduced Flanges (Reduced Weldnecks and Reduced Slip-ons)

Using design tools such as AutoCAD, flange specialists can develop prints and designs for clear, precise fabrication, no matter how specialized a project may be.

Common Flange Standards and Specifications

Special flanges and fittings and custom forgings can be designed to meet any number of unique specifications and standards. Some common classifications for custom pipe flanges include:

- AWWA, the American Water Works Association

- ASME, the American Society of Mechanical Engineers

- ANSI, the American National Standards Institute

- CL 125 Lightweight

- Tube Turns

- Large Industry Standard

- Metric System Flanges

Custom Flange Types

Regardless of custom sizing or specifications, the fundamental design of most flanges falls under six common styles created to close, connect, cover, or support pipes and pipe systems.

These flange types include:

- Slip-on Flanges – available in both standard and reduced sizes and both ring and hub style, manufactured to dimensions that will slide over a pipe with a snug fit

- Weld Neck Flanges – available in standard and reduced sizes, manufactured to the inside diameter dimensions of a pipe for attachment via welding

- Blind Flanges – available to seal both pipes and vessels

- Lap Joint Flanges – available in a range of sizes to pair with stub end fittings for easy dismantling

- Threaded Flanges – engineered to fit pipes with external threads for weld-free fits

- Socket-weld Flanges – designed with a socket fit and top weld for ideal inner flow in pipe systems

Material Grades and Performance

Custom pipe flanges can be manufactured from a wide variety of materials and material grades. Carbon steel is a popular solution, as are stainless steel and specialty alloys, depending upon the industry. Plate and forged are also common, as are titanium and aluminum for lightweight jobs.

Industries and Applications

Whether manufactured to ANSI, ASME, AWWA, or custom standards, flanges are critical to manufacturing, utility, and industrial applications around the world. Common uses for flanges include:

- Oil, gas, and chemical processing

- Power plants and nuclear power

- Food and beverage processing

- Manufacturing

- Industrial pumps, valves, and vessels

- Waterworks

- Heating systems

- Plumbing and mechanical systems

To learn more about custom flanges, flange manufacturing options, and industrial flange standards for your next project, reach out to the experts at Coastal Flange today.