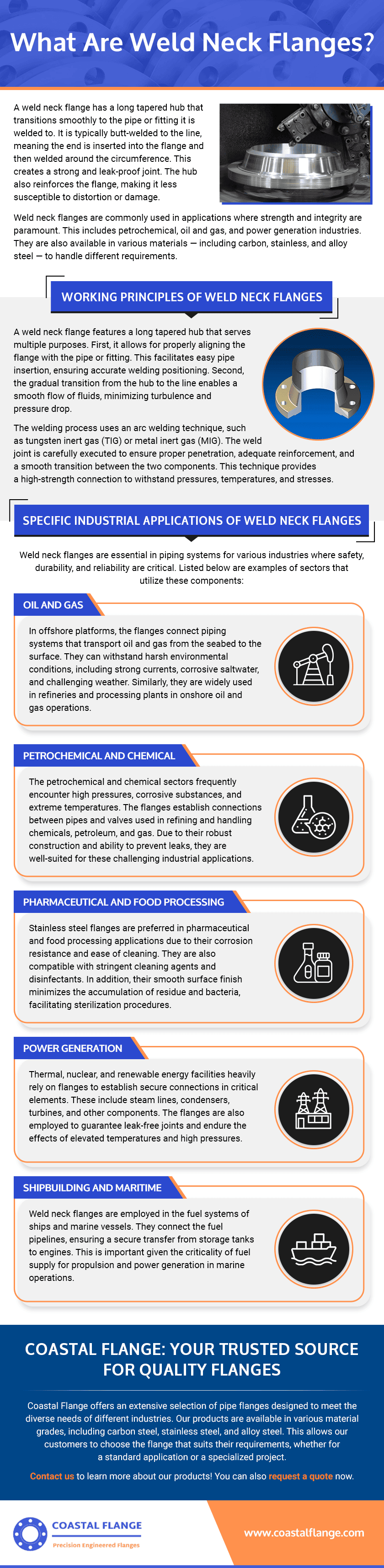

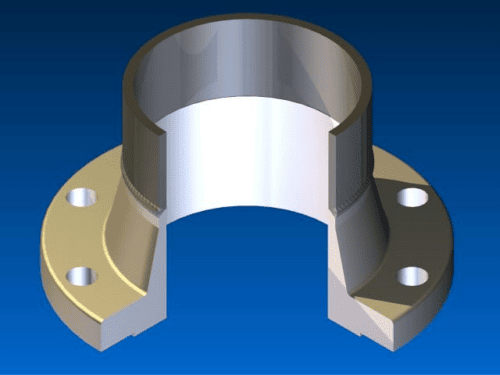

A weld neck flange has a long tapered hub that transitions smoothly to the pipe or fitting it is welded to. It is typically butt-welded to the line, meaning the end is inserted into the flange and then welded around the circumference. This creates a strong and leak-proof joint. The hub also reinforces the flange, making it less susceptible to distortion or damage.

Weld neck flanges are commonly used in applications where strength and integrity are paramount. This includes petrochemical, oil and gas, and power generation industries. They are also available in various materials — including carbon, stainless, and alloy steel — to handle different requirements.

This article delves into the fundamentals of weld neck flanges, including their working principles and specific applications.

Working Principles of Weld Neck Flanges

A weld neck flange features a long tapered hub that serves multiple purposes. First, it allows for properly aligning the flange with the pipe or fitting. This facilitates easy pipe insertion, ensuring accurate welding positioning. Second, the gradual transition from the hub to the line enables a smooth flow of fluids, minimizing turbulence and pressure drop.

The welding process uses an arc welding technique, such as tungsten inert gas (TIG) or metal inert gas (MIG). The weld joint is carefully executed to ensure proper penetration, adequate reinforcement, and a smooth transition between the two components. This technique provides a high-strength connection to withstand pressures, temperatures, and stresses.

Specific Industrial Applications of Weld Neck Flanges

Weld neck flanges are essential in piping systems for various industries where safety, durability, and reliability are critical. Listed below are examples of sectors that utilize these components:

Oil and Gas

In offshore platforms, the flanges connect piping systems that transport oil and gas from the seabed to the surface. They can withstand harsh environmental conditions, including strong currents, corrosive saltwater, and challenging weather. Similarly, they are widely used in refineries and processing plants in onshore oil and gas operations.

Petrochemical and Chemical

The petrochemical and chemical sectors frequently encounter high pressures, corrosive substances, and extreme temperatures. The flanges establish connections between pipes and valves used in refining and handling chemicals, petroleum, and gas. Due to their robust construction and ability to prevent leaks, they are well-suited for these challenging industrial applications.

Pharmaceutical and Food Processing

Stainless steel flanges are preferred in pharmaceutical and food processing applications due to their corrosion resistance and ease of cleaning. They are also compatible with stringent cleaning agents and disinfectants. In addition, their smooth surface finish minimizes the accumulation of residue and bacteria, facilitating sterilization procedures.

Power Generation

Thermal, nuclear, and renewable energy facilities heavily rely on flanges to establish secure connections in critical elements. These include steam lines, condensers, turbines, and other components. The flanges are also employed to guarantee leak-free joints and endure the effects of elevated temperatures and high pressures.

Shipbuilding and Maritime

Weld neck flanges are employed in the fuel systems of ships and marine vessels. They connect the fuel pipelines, ensuring a secure transfer from storage tanks to engines. This is important given the criticality of fuel supply for propulsion and power generation in marine operations.

Coastal Flange: Your Trusted Source for Quality Flanges

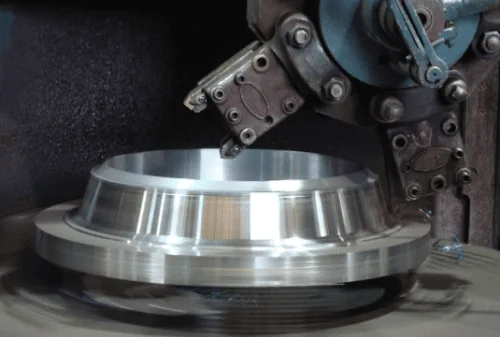

Coastal Flange offers an extensive selection of pipe flanges designed to meet the diverse needs of different industries. Our products are available in various material grades, including carbon steel, stainless steel, and alloy steel. This allows our customers to choose the flange that suits their requirements, whether for a standard application or a specialized project.

Contact us to learn more about our products! You can also request a quote now.