What is a Material Test Report (MTR)?

A material test report (MTR) quantifies the specific chemical and physical properties of a particular manufactured product. An MTR is a document used in the metal industry that certifies as a guarantee from the manufacturer to the supplier or end user. Coastal Flange sends Material Test Reports with every order or an email copy if specified or requested.

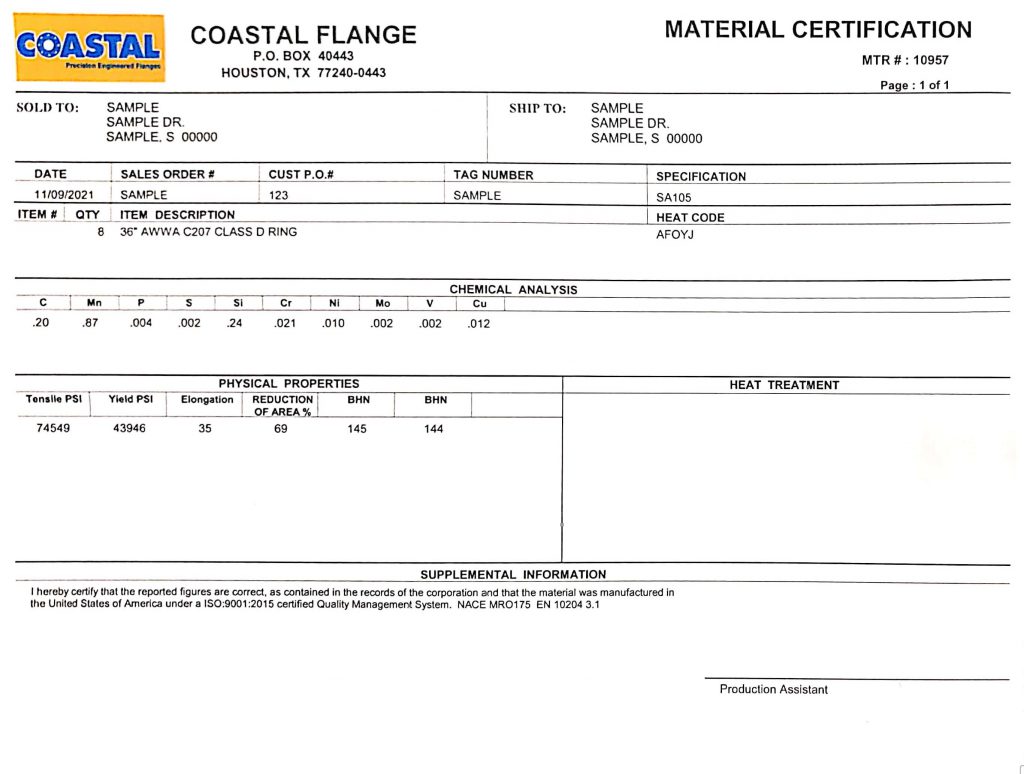

Here is a sample MTR from Coastal Flange:

Though some companies may have a different design for their reports, the information on them is typically the same.

How to interpret an MTR?

For first time viewers of a MTR it can be overwhelming upon first glance. However, once you know the basic components you will be a pro in no time.

Step 1: Customer Details

At the top of the page you will see details relating the manufacturer as well as the customer. You will see details such as customer purchase order information, sales order number, and tag number if applicable.

Step 2: Product Description and Specification

The next section pertains to the product quantity and item description. You will see the number of items with the same specification such as inside diameter, governing specification (AWWA, ANSI, ASME, etc.) and the product (blind, ring, weld neck, slip-on, etc.) classification. Depending on the raw material you may see thickness as well.

The product specification refers to the ASME and ASTM standards applied to a material. Most metals used in pressure application are required to meet a specific set of standards. ASME uses the “SA” prefix while ASTM includes the letter “A”.

Step 3: Heat Code (a.k.a. Heat Number)

Every MTR will include a heat code for identification. This code or “heat” is created from a single grouping of forgings generated from the same piece of billet in one forging session. Heat codes identify the physical and chemical composition of our flanges and custom materials. The heat code is stamped or engraved into the material like DNA.

Along with the “heat”, mills forge an additional piece known as the “test piece” or “coupon”. This piece undergoes destructive testing per ASME code to obtain physical traits. Chemical attributes include the percentage of elements prescribed in the acceptance range.

Step 4: Chemical Analysis

In the center of our MTR you will find the Chemical Analysis. This is the percentage values of Carbon (C ), Manganese (Mn), Phosphorus (P), Sulfur (S), Silicon (Si), Chromium (Cr), Nickel (Ni), Molybdenum(Mo), Vanadium (V), and Copper (Cu). The chemical breakdown of the steel determines if the product is fit for purpose according to the relevant ASME or ASTM standards.

Step 5: Physical Properties

On the left center of our MTR is Physical Properties. Physical Properties is determined through testing the mechanical properties that appraise a material’s tensile strength (PSI), yield point (PSI), elongation, reduction of area percentage, and Brinell hardness number (BHN).

Yield point is where the stress of a force permanently changes the shape of the material. Tensile strength is the force required for the material to break or fail. Both tensile strength and yield point are measured in pounds per square inch (PSI). The reduction of area percentage is measured by the difference of the cross-sectional area of a tensile test piece before and after breakage.

Elongation is how much a material can stretch or bend in relation to its original length. Elongation is calculated as the percentage difference between yield point and tensile strength. The greater the elongation, the more ductility a material has.

While strength is the amount of force a material can withstand before failing and toughness is the ability to resist fracturing, harness is the ability to withstand friction and abrasion. The Brinell hardness test (BHN) is determined by using a steel indenter and applied force to dent a material. The size of the dent determines the Brinell hardness number (BHN).

Step 6: Heat Treatment

If applicable to your product, you may see a heat treatment. Heat treatments alter the physical and/or chemical attributes of a material. Treatments can include heating or chilling the material in extreme temperatures to ensure the desired effect. This can include the hardening or softening of a material. A few commonly used heat treatments include: tempering, annealing, normalizing, austenitizing, carburization, hardening, and more.

Step 7: Quality Assurance

A quality assurance statement that confirms compliance from the manufacturer is often placed on the MTR. Coastal Flange uses ISO:9001:2015 certified Quality Management System practices to ensure the quality expectations are being met.

Reasons to use a manufacturer who supplies MTRs

When looking for a manufacturer it is highly recommended that you work with a company provides MTRs. This is your documentation and assurance that the product meets the necessary standards for your project.

About Coastal Flange

Coastal Flange is a manufacturer and distributor of pipe flanges form ½” through 200” OD in ASME, AWWA, ANSI, industry standard, and large diameter custom engineered flanges. The Jersey Village, Texas facilities are located in the hub of the oil, gas, and petrochemical industry, which allows easy access to rail, truck, air, and water transportation. Celebrating 36 years in business and thousands of flanges shipped each year, Coastal Flange is dedicated to meeting all your pipe flange needs.

Contact Coastal Flange with any questions or to receive a quote tailored.

Phone: 713-937-3333

Email: Sales@coastalflange.com