ANSI flanges are industrial fittings that connect pipes or equipment that meet the American National Standards Institute (ANSI) specifications. They are designed to make leak-proof secure connections, ensuring the safe and smooth flow of liquids, gases, or other substances. They are also essential in various piping systems across multiple industries, including oil and gas and chemical processing.

Choosing the appropriate flanges for a specific application is crucial. If the wrong flange is used, it can result in leaks, breaks, or complete system failure. Such matters can create dangerous working conditions, expensive downtime, damage to equipment, and harm to people or the environment. With that in mind, here are key considerations relevant to selecting the right flange:

-

Pressure Rating

The pressure rating of an ANSI flange is the maximum pressure it can withstand before experiencing leakage or failure. Flanges are often rated based on the highest pressure of the fluid or gas they will have to accommodate. Therefore, selecting a flange with a pressure rating that exceeds the system’s maximum force is crucial to prevent ruptures and equipment damage.

ANSI flanges have varying pressure ratings depending on the particular type of flange and its intended application. Although it can vary widely, the typical pressure ratings are between 150 and 2500 pounds per square inch (PSI). This information is normally found on the flange or the manufacturer’s specifications. -

Flange Material

Flange material selection is typically based on the fluid or gas being transported. Carbon steel and stainless steel are frequently used materials for ANSI flanges. Carbon steel is a cost-effective option and is usually suitable for applications with moderate temperatures and pressures. On the other hand, stainless steel is ideal for environments requiring corrosion resistance, such as chemical processing facilities.

-

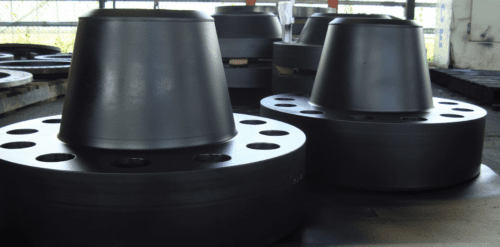

Flange Type

Flange types can differ in size, shape, and attachment method to the piping system. Therefore, it is highly recommended to consult with a qualified engineer or manufacturer to determine the appropriate type for the application. Examples of the most common types of an ANSI flange include the following:

- Blind flanges: seals off the end of a pipe or vessel and are ideal for applications where maintenance or cleaning is required

- Slip-on flanges: easy to install and suitable for low-pressure applications

- Socket weld flanges: attached to the piping system by welding and used in high-pressure and high-temperature applications

- Threaded flanges: screwed onto the piping system and used in low-pressure applications

- Weld neck flanges: welded to the piping system and used in high-pressure and high-temperature applications

-

Bolt Specification and Torque Values

The bolts used to attach the flanges to the piping system must be strong enough to withstand the system’s pressure and stresses. Therefore, the bolt material, size, length, and thread type are all important factors. Meanwhile, torque values refer to the force applied to the bolts to achieve a secure and leak-proof connection. They are calculated based on the bolt size, material, and pressure rating.

Following the manufacturer’s torque specifications when installing the flanges is crucial to ensure a proper connection. Over-tightening the bolts can cause the flange to deform, resulting in leaks. Conversely, under-tightening the bolts can cause the flange to separate from the piping system, resulting in unsafe working conditions. -

Dimensions and Sizing

The size of an ANSI flange is dependent on the size of the pipes that need to be connected. Flanges come in various sizes, ranging from 0.5” to over 60” in diameter. Moreover, the dimensions of the flange — such as the flange face and bolt circle — are critical to ensure proper installation. ANSI flanges are categorized into different classes, each with specific dimensions for these dimensions, ensuring that they match the needs of particular applications.

Choose Coastal Flange for High-Quality ANSI Flanges

Coastal Flange is the ultimate choice for all your ANSI flange needs! With over 100 years of experience, we are a leading manufacturer specializing in producing ANSI B16.5 flanges from Class 150 to Class 2500. We also ensure to adhere to the most rigorous industry standards and certifications.

Contact us today to learn more, or request a quote and partner with us now! Count on us to deliver the highest quality products and services.