The following are the 6 types of flanges most common flanges in process piping systems.

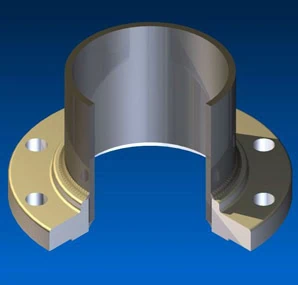

1. Slip On

As made obvious by their name, these pipe flanges slip over the pipe. They’re manufactured with an inside diameter that is slightly bigger than the pipe’s outside diameter. These attachments are connected to the pipe via fillet weld at the top and bottom of the flange.

Slip on pipe flanges are typically provided with a raised or flat face. When a raised face is necessary for slip on pipe flanges, the standard height is 1/16″ for slip on pipe flanges under 400#. For slip on pipe flanges of 400# and up, the standard slip on pipe flange raised face height is 1/4″.

Coastal manufactures slip on pipe flanges in all steel material grades, including carbon slip on pipe flanges, stainless steel slip on pipe flanges and alloy slip on pipe flanges.

Slip on pipe flanges in stock include AWWA slip on pipe flanges, ANSI slip on pipe flanges, Pressure Vessel slip on pipe flanges and slip on pipe flanges that match the OD and drilling of ASME flanges.

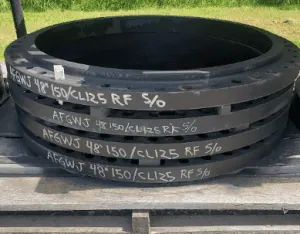

2. Weld Neck

Weld neck flanges are easily recognized by the tapered hub where the pipe welds to the flange. This transfers stress from the flange to the pipe instead. It also reduces the stress concentration from the base of the hub. Weld neck flanges are often used for applications where high pressure is a factor. The inside diameter of the flange is designed to match the pipe’s inside diameter. Weld Neck Pipe flanges with a hub have published specifications that range from 1/2″ thru 96″. Our company provides these in all material grades, specifications and sizes.

Weld neck pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for weld neck pipe flanges, the standard height is 1/16″ for weld neck pipe flanges under 400#. For weld neck pipe flanges of 400# and up, the standard weld neck pipe flange raised face height is 1/4″.

Coastal Flange manufactures weld neck pipe flanges in all steel material grades, including carbon weld neck pipe flanges, stainless steel weld neck pipe flanges and alloy weld neck pipe flanges. Coastal Flange also has many different weld neck pipe flanges in stock and ready to ship. Weld neck pipe flanges in stock include ANSI B16.5 weld neck pipe flanges, ASME B16.47 Series “A” weld neck pipe flanges, ASME B16.47 Series “B” weld neck pipe flanges, Pressure Vessel weld neck pipe flanges.

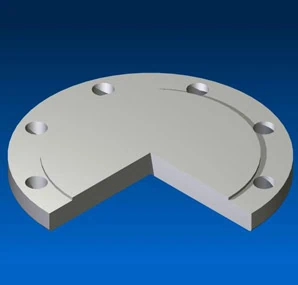

3. Blind

Blind pipe flanges are used to seal the end of piping systems or pressure vessel openings. They are commonly used for testing the flow of gas or liquid through a pipe or vessel. Blind pipe flanges also allow for easy access to the pipe in case work must be done inside the line. They are oftentimes used for high pressure applications.

Blind pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for blind pipe flanges, the standard height is 1/16″ for blind pipe flanges under 400#. For blind pipe flanges of 400# and up, the standard blind pipe flange raised face height is 1/4″.

Coastal Flange manufactures blind pipe flanges in all steel material grades, including carbon, stainless steel, and alloy blind pipe flanges. Coastal also has many different blind pipe flanges in stock and ready to ship. Blind pipe flanges in stock include ANSI B16.5 blind pipe flanges, ASME B16.47 Series “A” blind pipe flanges, and ASME B16.47 Series “B” blind pipe flanges.

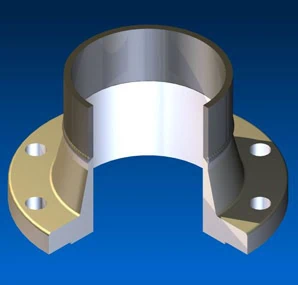

4. Lap Joint

Lap joint pipe flanges slide directly over the pipe and are most commonly used with stub end fittings. A pipe is usually welded to the Stub End and the Lap Joint pipe flange is free to rotate around the stub end. The benefit of this is that there will not be any issues with bolt hole alignment. Lap Joint pipe flanges are often used for applications that require frequent dismantling.

Slip on Pipe flanges with a hub have published specifications that range from 1/2″ thru 24″. Sizes above 24″ are produced as lap joints to slip on dimensions. Coastal Flange provides Lap Joint pipe flanges in all material grades, specifications and sizes.

Coastal manufactures lap joint pipe flanges in all steel material grades, including carbon, stainless steel, and alloy lap joint pipe flanges.

5. Threaded

Threaded pipe flanges are similar to slip-on pipe flanges except the bore of threaded pipe flange has tapered threads. Threaded pipe flanges are used with pipes that have external threads. The benefit of these pipe flanges is that it can be attached without welding. Threaded pipe flanges are often used for small diameter, high pressure requirements.

Threaded pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for threaded pipe flanges, the standard height is 1/16″ for threaded pipe flanges under 400#. For threaded pipe flanges of 400# and up, the standard threaded pipe flange raised face height is 1/4″. Today, threaded flanges are used almost exclusively for utility service such as instrument air, plant air, nitrogen, potable, and raw water.

Coastal manufactures threaded pipe flanges in all steel material grades, including carbon threaded pipe flanges, stainless steel threaded pipe flanges and alloy threaded pipe flanges. Coastal also has many different threaded pipe flanges in stock and ready to ship.

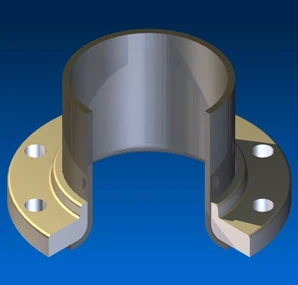

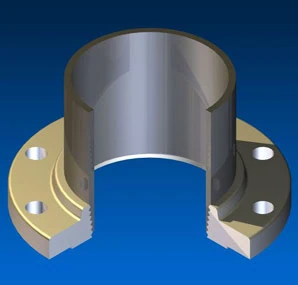

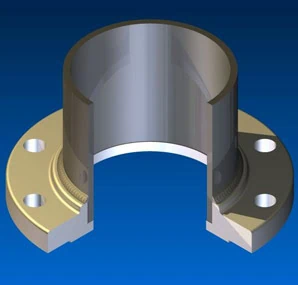

6. Socket Weld

The Socket weld Flange is similar to the Slip on Flange as the pipe slips inside the Flange into a socket and is secured with a fillet weld at the hub on the back side of the flange. Per ASME B31.3 Socket weld Flanges are only to be used in noncritical applications where pressure, temperature or product corrosion is not an issue.

Socket Weld pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for socket weld pipe flanges, the standard height is 1/16″ for socket weld pipe flanges under 400#. For socket weld pipe flanges of 400# and up, the standard socket weld pipe flange raised face height is 1/4″.

Coastal Flange manufactures socket weld pipe flanges in all steel material grades, including carbon socket weld pipe flanges, stainless steel socket weld pipe flanges and alloy socket weld pipe flanges. Coastal Flange also has many different socket weld pipe flanges in stock and ready to ship.

Contact Coastal Flange with any questions or to receive a quote tailored.

Phone: 713-937-3333

Email: Sales@coastalflange.com