Stud bolts for flanges are the bolting material or fastener used to tighten the flange joint connection.

ASME B16.5 Code

The American Society of Mechanical Engineers (ASME) began creating code for the piping industry in 1922. ASME created B16, a universal standard for engineers, architects and manufacturers for the purpose of unifying and developing codes for pipe flanges and fittings (and later valves and gaskets).

Bolts for Pipe Flanges

The flange type, depending on the pipe diameter and pressure rating will determine the quantity and size of the required bolt.

Types of Bolts

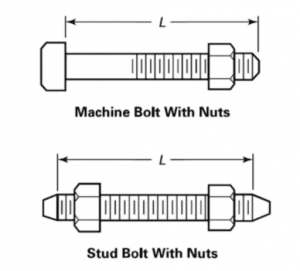

In Petrochemical industry stud bolts and hex machine bolts are used for connections. The Stud Bolt is a thread on full-lengths or at both ends, while Hex Machine Bolt has a hexagonal head with one nut. Both the nuts and head are six-sided.

Stud Bolts

ASME flanges have a minimum of four bolt hole. The bolt hold number increases depending on the size of the flange diameter, the working pressure, temperature, and flange material.

Stud Bolts lengths are defined in ASME B16.5 standard. The length of the stud bolt should enough to cover the entire Nut plus 1.5 to 3 threads exposed. Long studs are not recommended as it increases the chance of corrosion and can damage the exposed threads.

Hex Machine Bolts

Hex Machine bolts are commonly referred to as hex bolts. The bolts have a thread at one end and a hexagonal nut on the other end. Washers are often used with a bolt to prevent excessive load to the flange.

Hex Nuts

Hex nuts are defined in ASME B18.2.2, and even as bolts the threaded in ASME B1.1. Depending on project specification, nuts must be both sites chamfered or with one side a washer-face.

Contact Coastal Flange with any questions or to receive a quote tailored.

Phone: 713-937-3333

Email: Sales@coastalflange.com